Rose distillation - in Turkey

Essential Oils Production & Conservation/

23.02.24

Rose distillation in Turkey

In June 2000 I saw the full production cycle of Turkish rose oil.

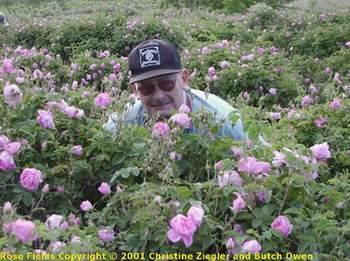

I was invited there by Butch Owen (above), an American who lived in Turkey

for around 20 years. Since he speaks the language like a native, he has direct

contacts with growers, producers and miscellaneous other people. He is treated

by them as an old friend, which of course opened doors that might be closed to

other people.

The organisation that I visited was the State controlled co-operative. They

have a large office, laboratory and cosmetics production building. On the same

site they process small amounts of rose concrete. They have 5 distillation

plants in the Isparta area (consisting of a total of 80 primary stills and 10

secondary stills). The roses come into those from the surrounding small farms.

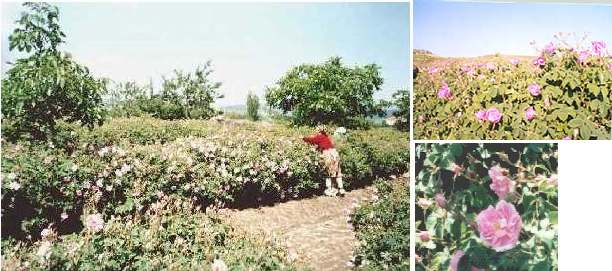

It was interesting that the small family-owned farms did not have vast fields of

roses, but rather they had many small fields interspersed by fields growing all

kinds of other crops. Each farm seemed to have just a few rose fields making

self distillation uneconomic. Hence the reason for co-operative distillation facilities.

The bushes are extremely prolific in flowers and keep producing roses for a few

weeks. This means picking occurs almost every day. It was interesting that the

rose bushes are left in the same location for 40 years or more, adding just

animal manure as fertiliser. They trim the bushes back annually, and every 8 or

10 years they are cut to the ground.

The rose bushes are about waist height making for easier picking. This is

mostly done by the women from the villages who are paid by weight picked.

The speed that they can pluck the flowers from the bushes is quite remarkable.

The night before we arrived it had rained hard, so we thought harvesting might

be postponed. However, the following morning it was sunny and they picked

the flowers as normal. We were told it just meant they had to get them to the

still a bit quicker than normal to prevent fermentation.

Picking begins before the sun rises and stops around 11 A.M. Once picked, the

roses are put in sacks which are taken by tractor trailers or old farm trucks to

the nearest distillation plant. On arrival the sacks are quickly emptied into 40

year old seasoned copper stills. The first distillation is in a range of about 8

large stills. Each takes 1500 kilos of water and 500 kilos of rose petals.

This first distillation takes about an hour and three quarters and produces a

layer of thick brown rose extract around an inch deep in the glass flask. This

material is so valuable that it is never sold - despite the hype of some

aromatherapy suppliers. When the first distillation is complete the distillation

water is pumped to the second distillation units. Here the 'cohobation' occurs

for about half an hour; the final result being rose hydrosol and the second rose

oil. Later, the first and second rose oils are blended to get the final product -

rose otto.

As is common with distillation, the rosewater and oil do not smell so good

when fresh. The beautiful fragrance takes a few weeks to appear. In the case

of rose oil it can take a year or more to obtain its best aroma and it continues

to improve if stored properly.

The distillation plant is set above concrete channels in the floor. These are

where the waste still jacketing water and the spent roses are discharged. The

channels lead into an earth lagoon outside the factory. Once the waste dries

out, the farmers use this on their fields as mulch.

The hot rosewater is led off into large stainless steel storage tanks (above

right) direct from the still. This of course reduces the possibility of atmospheric

microbial contamination.

The Turks prize this rose oil so much that these factories are only open a few

weeks of each year. Government regulations prohibit using these stills for

anything else for fear of contaminating them. So imagine a factory in the West

being open for just a couple weeks and what that will do to the price of the end

product. In addition it requires approximately 4 metric tons of rose petals to

make one kilogram of rose otto. So when people think rose oil is so expensive,

perhaps you can see why.

At their H.Q. I saw the processing of the flowers into concrete. This was only a

small scale operation just to keep some of their big overseas customers happy.

Here the rose flowers are placed into a large mixing machine where they are

rotated along with Hexane as a solvent. The liquid extract is filtered and

extracted twice with hexane before finally pouring into steel cans. The hexane

solvent is recycled and used over and over again. The cans have a hole cut out

of the lid so that as the liquid sets hard, the residual hexane given off just

evaporates. This 'concrete' is then shipped to their customers who will

reprocess it to make an absolute.

This organisations rose oil is certainly of the highest quality which is of course

reflected in the price. You can get what is called "village oil", this is produced in

small direct fired stills in the villages, but its fragrance is dreadful for

aromatherapy purposes. It has these caramelised notes that certain perfumers

prefer, but the caramel notes are due to the overheating of the oil in the old

stills. I was told by several experts that certain private producers in Turkey

purchase these village oils, blend them with cheaper imported rose oil before

reselling it as "Turkish otto". This fraud can easily be detected with GC testing,

but my guess is a lot of this lower grade blended oil finds its way into the

aromatherapy market.

Also in their HQ, they have production facilities for making soaps, shampoos

and skin creams using rose oil and water. It was nice to see that they also have

laboratories capable of excellent quality control and research on their products.

While we were there, the chemist was doing challenge testing for bacteria and

testing of PH on some products. The entire process in the products lab. is

mechanical and none of the products are touched by human hands. The

laboratory is proud of the ISO 9002 Certificate they have on the wall in the

entrance way.

The main analysis of rose oils was undertaken by the Aromatic and Medicinal

Plant and Drug Research Center at Andalou University. This department has

some of the finest phytochemical laboratories in the world and really there is

little they cannot test for on botanical extracts.

To summarise: Turkish rose oil and rosewater from the then State controlled

organisation are among the finest products one could wish for. I have visited

several growing areas around the world, but was most impressed by their set-

up and the pride they took in the quality of their products. If in time the rose

oil production is privatised, and with the general development in Southern

Turkey, it remains to be seen if this reduces the availability of this fine oil.

Clearly the small farmers would get a far higher income working in and for

their fast developing tourist industry.

So what's Rose oil good for then?

Here is an extract from the basic information files on essential oils. The

professional monographs of course have far more.

BATHS: Rose makes a wonderfully relaxing, luxurious bath, perfect for relaxing

after a stressful day at work. A few drops in the bath can leave a long lasting

gentle fragrance on the skin, ideal for parties or for seduction.

MASSAGE: An ideal oil for massage. It is perfect for helping relieve stress-

related conditions and for mild psychological ailments. Due to its strong

influence on the mind and emotions, it may help improve recovery from a wide

range of illnesses for example: Anxiety, P.M.S. menstrual disorders of nervous

origin, insomnia, headaches, and nervous palpitations. It is good for soothing

skin care preparations, for mild burns and minor skin abrasions, for hay fever

and allergic skin disorders and finally as an aphrodisiac.

A trip to Turkey - Rose production and other sights.

Here are the notes of a talk I gave about the trip to Turkey in June 2000. Some

of this is in the file above about Rose oil production, but there is some

additional information which some may find of interest. The notes are only

slightly tweaked to take account of the passage of time.

This article should be packed with photos, but Butch is always too busy with

planting, hunting, writing on facebook, etc. to let me know which ones of his

hundreds that I can use.

I had been invited to Turkey by Butch Owen, an American who has lived in

Turkey for 18 plus years. At that time he had a large business based in Ankara.

He dealt in bulk essentials oils, herb teas and other Turkish products most of

which were shipped to the USA. He was also the Turkish director of Sata travel,

a large agency that handles US military travel worldwide. He has spent most of

his life in the US military mainly as an officer in their police services, and been

in many countries as a result, but at heart he is still a country boy having

grown up in the backwoods of Alabama. Since our trip, he has married again

and settled in his retirement in Tennessee. Having come from an environment

where herbal medicine was the only medication for many, he has a deep

interest in botanical medicine and ensuring he only deals in unadulterated

products. This led to an association being formed with Professor Baser of

Andalou University who tested all his oils - more on that later.

Butch speaks Turkish like a native and had direct contacts with growers,

producers and miscellaneous other people. He is treated by them as an old

friend, which of course opened doors that might be closed to other people. He

was well known in the bars of Ankara frequented by Military and political

figures alike.

His language skills got a speeding fine reduced by half because he chatted up

the cop who pulled us over, whereas a group of Turkish politicians who bombed

by us at very high speed, got hit for the full amount. I think as a little aside

that this was rather interesting as it showed the police force were defiantly

impartial. Many people have the impression that Turkey is almost a military

state, but this is far from the truth. In the UK we were fed a constant stream

of misinformation by our media about Turkey and other countries. Don’t

believe 1% of what you hear on the news or read in comics (some people call

them newspapers)!!

A short history:

The history of roses and rose oil production in turkey is ancient. Essential oils

have been produced in the Anatolian region as a home and village activity for

hundreds and possibly thousands of years. They used simple copper stills

consisting of two vessels one on top the other. The bottom vessel contains

plant material and water. The top one is filled with cold water and acts as the

condenser. As the oil condenses it is led out through a small copper tube.

These home stills were mainly used to produce a home made drink distilled

from fermented raisins, dried figs and mulberries.

No one knows how long rose oil has been produced in that area, but we do

have records showing that in the reign of king Midas (circa 700BC) that roses

were highly regarded. It is good to consider the known history of this region;

the oldest village in the world has been found in Turkey dated to around 6500

BC. Turkey has also been a meeting place of many ancient civilisations all

contributing a broad spectrum of knowledge on how to utilise plant materials.

The southern coastal area has numerous Ancient cities dating back to the dawn

of civilisation. It was on a river at Tarsus on the southern Mediterranean

Turkish coast that Cleopatra had her famous meeting with Antony. With her

reputation of enjoying fine perfumes, perhaps that might have contributed to

the choice of that location. This whole area produces fine wines and the plants

needed to produce perfumes and unguents.

To more modern times:

It is known that dealers in essential oils traded in the 1700s in Turkey.

However, the production of rose oil on a large scale was triggered by the

founder of modern turkey Kemal Ataturk. His mausoleum in Ankara is well

worth a visit, a very special place. He visited Isparta in the 1920s, saw the

local village production, and ordered the building of modern rose extraction

facilities.

An explanation of the term ‘otto’ often applied to rose oil: This comes from the

Ottoman empire and should only refer to an oil from that part of the world. The

term ‘attar’ should never apply to a hydro distilled oil. A true attar is an extract

originating in India containing rose and sandalwood, but the aromatherapy

world is packed with such deliberately misleading hype.

So here goes on rose oil itself

Before going to the Cappadocia region and to Isparta which is the big rose

production area, we called in at a couple of other places which I will tell you

about at the end. After those visits we then headed out for Isparta which is I

think around 250 miles south of Ankara and lies about 80 miles inland from the

southern Mediterranean coastal resorts. Turkey is in fact a very big country; we

were surprised to find we had done 2000 miles in a relatively limited area.

We got to Isparta town that night and thanks to Butch’s staff back home, we

were already booked into a nice central hotel THEN ($16.26 a night-about

£10.50). The next day we headed out of town to the state controlled rose

production co-operative called Gulbirlik. They have a large office, laboratory

and cosmetics production building. On the same site they also process small

amounts of rose concrete. They control 5 distillation plants in the Isparta area

(consisting of a total of 80 primary stills and 10 secondary stills). The roses

come into those from the surrounding small farms.

At Gulbirlik we had about 2 hours of meetings with the deputy director and

director. These people are political appointments and have little idea about how

western business works. All they seemed interested in was Butch trying to get

back their big US customers that were lost years previously because of internal

politics. However, poor old Butch trying to get them to commit to a base price

around which he could negotiate with US companies was just impossible. This

way of doing business is regrettable because they told us they could easily

double existing output from the 1,000 kilos this year, if they had the

customers. Currently most of their production goes to France. Knowing what I

do about the French trade in essential oils, I think you would be hard put to

get an unadulterated Turkish rose oil back out of that country.

After lunch we were taken out to one of the distillation plants some distance

out in the country. It was interesting that the small family-owned farms did not

have vast fields of roses, but rather they had many small fields interspersed by

fields growing all kinds of other crops. Each farm seemed to have just a few

rose fields making self distillation uneconomic. Hence the reason for co-

operative distillation facilities.

The night before we arrived it had rained hard, so we thought harvesting might

be postponed. However, the following morning it was sunny and they picked

the flowers as normal. We were told it just meant they had to get them to the

still a bit quicker than normal to prevent fermentation occurring.

The rose bushes are about waist height making for easier picking. This is

mostly done by the women from the villages who are paid by weight picked.

The speed that the women can pluck them off the bushes is quite remarkable.

The bushes are extremely prolific in flowers and they keep producing roses for

several weeks. This means they have to be repicked almost every day. It was

interesting that the rose bushes are left in the same location for 40 years or

more, just adding animal manure as fertiliser. They trim the bushes back

annually and every 8 or 10 years they cut them to the ground. The Roses are

all Rosa damascena variety kazanlik. This is the same variety that the

Bulgarians use and is believed to have been developed in Bulgaria originally

part of the Ottoman empire. Despite being the same variety, the chemical

composition of the oil produced in Turkey is different and many consider it

superior in fragrance to the Bulgarian oils.

Rose picking begins before the sun rises and stops around 11 a.m. Once

picked, the roses are put into sacks which are then taken by tractor trailers or

old farm trucks to the nearest distillation plant. This site of stacks of sacks of

pink roses is quiet wonderful.

Upon arrival the sacks are quickly unloaded onto a high floor overlooking the

stills. From here they are emptied into the 40 year old seasoned copper stills.

The first distillation is done in a range of about 8 large stills. Each takes 1500

kilos of water and 500 kilos of rose petals.

This first distillation takes about an hour and three quarters and produces a

layer of thick brown rose extract around an inch deep in the glass flask. This

material is so valuable that it is never sold despite the hype you will hear from

some aromatherapy suppliers.

When the first distillation is complete, the distillation water is pumped to the

second distillation units. Here the cohabitation occurs for about half an hour;

the final result being rose hydrosol and the second rose oil. Later, the first and

second rose oils are blended to get the final product - rose otto.

As is common with distillation, the rosewater and oil do not smell too good

when fresh. The beautiful fragrance takes a few weeks to appear. In the case

of rose oil it can take a year or more to obtain its best aroma and it continues

to improve if stored properly. The oil I saw distilled in June will not be sold until

the following summer. Incidentally, I visited Kent (UK) to see the English

Lavender oil distilled. As with rose that also does not smell too good when it is

fresh. It takes a few months to develop its best aroma.

The rose stills are set above concrete channels in the floor. These are where

the waste still jacketing water and the spent roses are discharged. The

channels lead into an earth lagoon outside the factory. Once the reside dries

out, the farmers use this on their fields as mulch.

The hot rosewater is led off into large stainless steel storage tanks direct from

the still. This of course reduces the possibility of atmospheric microbial

contamination. Despite this, there is no way I would advocate the internal use

of this rosewater unless it had got a proper preservative added.

The Turks prize this rose oil so much that these factories are only open a few

weeks of each year. Government regulations prohibit using these stills for

anything else for fear of contaminating them. So imagine a factory in the west

being open for just a couple weeks and what that will do to the price of the end

product. In addition, it requires approximately 4 metric tons of rose petals to

make one kilogram of rose otto. So when people think rose oil is so expensive,

perhaps you can see why.

At the Gulbirlik H.Q. I saw the processing of the flowers into concrete. This was

only a small scale operation just to keep some of their big French customers

happy. Here the rose flowers are placed into a large mixing machine where

they are rotated along with hexane as a solvent. The liquid extract is filtered

and extracted twice with hexane before finally pouring into steel cans. The

hexane solvent is recycled and used over and over again. The cans have a hole

cut out of the lid so that as the liquid sets hard, the residual hexane just

evaporates. This concrete is then shipped to their customers who will reprocess

it to make an absolute.

The Turkish co-op distilled rose oil is certainly of the highest quality which is of

course reflected in the price. You can get what is called "village oil", this is

produced in small direct fired stills in the villages, but its fragrance is dreadful

for aromatherapy purposes. It has these caramelised notes that certain

perfumers prefer, but the caramel notes are due to the overheating of the oil in

the old stills. I was told by several experts that some private suppliers in

Turkey purchase these village oils, blend them with Turkish hydro distilled oils

(and even imported Bulgarian rose oil) before reselling it. This can easily be

detected with GC testing, but my guess is a lot of this lower grade blended oil

finds its way into the aromatherapy market.

Also in the co-operative’s H.Q. they have production facilities for making soaps,

shampoos and skin creams using rose oil and water. It was nice to see that

they also have modern laboratories capable of excellent quality control and

research on their products. The entire process in the products lab. is

mechanical and none of the products are touched by human hands. The

laboratory is proud of the iso 9002 certificate they have on the wall in the

entrance.

While we were there, the chemist was doing challenge testing for bacteria and

testing of ph on some products. I have always nagged people about the

dangers of using unpreserved hydrosols. While there the chemist tested out

different levels of benzoate in the rosewater so that we could see how it

affected it. The ph level hardly changed and at less than 0.5% there was little

perceptible change in fragrance although I thought it improved the potency of

the fragrance slightly. I can’t emphasise too strongly how important it is to

only use these hydrosols if you know they are safe from microbial

contamination. Many aromatherapy suppliers either don’t bother to test, or sell

them with preservatives but as "totally natural" knowing full well they are not.

The main analysis of the rose oils is undertaken by Prof. Baser at Andalou

University under contract. His department has some of the finest

phytochemical laboratories in the world. There is little they can’t test for on

botanical extracts.

Turkish rose oil and rosewater from the state co-operative is the most highly

controlled and excellent quality product one could wish for in aromatherapy. I

have visited several growing areas around the world, but was most impressed

by their set-up and the pride they took in the quality of their products.

Following our trip to the distillation plant we were taken the village of Kilic to

meet the mayor who Butch also knew. This village was the centre of an

important agricultural area. The mayor is the person in charge of production

and was a key political figure. I asked him about what other things they

produced? It included all the normal vegetable one would expect in a warm

fertile area, but also several citrus fruits, cherries, melons and walnuts. This

part of Turkey has a staggering range of fruits, nuts and vegetables. They have

a wonderful cherry juice which is everywhere in cartons and other soft drinks -

wish we could get it. They also have the biggest and best hazelnuts I have ever

seen. When I Asked the mayor where most of their exports went, the answer

was France!

Turkey does also produce other essential oils. Three types of origanum

(marjorana, onites and multiflorium) grow wild, as do salvia fruticosa and

rosmarinus officinalis. Butch took me to one massive ruined Greek city and all

around the ruins was wild oregano. The locals let their cattle graze among

these ruins, so I guess the meat would be ready seasoned. He has also found

one grower of lavender, but guess where the whole production goes - France.

They have a huge citrus industry, but currently do not produce the essential

oils. I would suspect that Turkish neroli would be wonderful because of the

climate. Years ago they did produce jasmin, but it seems that no longer occurs.

Now back to the earlier part of my trip.

The day before we headed to Ispata, Butch took me to meet Professor Baser at

the aromatic and medicinal plant research centre at Anadolu university. I was

really delighted to be given this opportunity because he is one of the top

phytochemists in the world. He has 4 plants named after him and so is also a

practical botanist. Believe me, I am rarely left in awe at scientists, but he is

really something special and is not an elitist academic. This man who is head of

a huge plant research department took 4 hours out of his schedule to show us

his department and even entertain us to lunch. Prof. Baser is a true

phytochemist in that he uses that magic word “synergy” when talking about

chemicals in plants. You will only find true experts in that field who

acknowledge such a thing exists. In other words they do not just look at

individual chemicals and how they work, but look at the wider picture. It was

interesting that Prof. Baser did part of his training at Chelsea university UK,

one of the few courses that teach practical phytochemistry. He also knew the

person that taught me chemistry when I did herbal training.

The laboratories he controls are among the finest in the world with millions of

pounds worth of equipment. I have never seen so much advanced equipment

anywhere, from the latest glcs right through to mass spectrometer and atomic

structure detection equipment. On the more practical side they have all types

of extraction equipment from ordinary distillation right through to co2 and

even spray drying. They have a commercial scale fractionation plant; a type of

closed still that can remove undesirable components from essential oils. For

example, if it is a bad year for oregano oil, they can remove unwanted

chemicals from an oil in order to boost the level of carvacrol which the price of

the oil is based on. This is not adulteration because nothing is being added;

rather it is a natural form of standardisation. At the other end of the scale they

have wonderful microdistillation equipment so that a student can gather a few

leaves from a plant, distil a few drops of oil and then analyse it, or if plant

hunting in the wild, a little piece can be bought back for analysis.

Just to round things off, they can run any kind of tests on a plant extract, from

toxicity using in vitro testing, or testing on rats if necessary, incidentally they

rarely do this unless it is vital. They can do dermal testing in vitro, or on the

thousands of students in the university who are always happy to earn a bit of

extra cash. Finally they can do therapeutic efficacy testing. An ongoing project

is testing one variety of Turkish oregano oil for anti cancer activity. They have

already published a paper where rats with melanoma have healed after the

application of Turkish oregano oil. Prof. Baser told me he was so convinced that

oregano had anti cancer activity that him and his family take a glass of the

distillation water every. Please bear in mind though they have access to the

freshly distilled water, I would not use commercial stuff for this. However, if

one can get this variety of dried herb, it is dead easy to make a tea from it

which is more or less the same as a hydrosol.

I was given a copy of a book his students put together to celebrate his 50th

birthday. I can’t tell you what a pleasure it was to talk to such an eminent but

still practical scientist.

Next stop before Isparta was the tomb of King Midas. Now thought to be

his fathers tomb.

We were driving out of Ankara and passed a sign to Gordion and to its ancient

palace. Butch asked me if I would like to have a look. The palace is nothing

much; it is one of those ancient sites that has been built and rebuilt a hundred

times. There are just some large walls left, excavated from the mound which

has built up over two thousand odd years. However, there was also a tiny sign

pointing to a village a couple of miles away saying ‘tomb of King Midas’. Well

we had to take a look at that. Within a couple of minutes of driving towards

this village you could clearly see the tomb, it was very much like Silbury hill

(UK) in that this 53 metre high burial mound dominates the valley.

King Midas supposedly founded the ancient city of Ancyra, the modern Ankara.

He is referred to in Assyrian records as Mitas of Mushki, who paid tribute to the

Assyrians after being defeated in battle. He is thought to have reigned from

725 BC to 696 BC. He is the figure of legend who is supposed to have had

problems because everything he touched turned to gold including his food. This

is of course a fairy tail, but the person was real. Midas is supposed to have

cleansed himself of the curse by washing in the local river. Several of the rivers

in this part of Turkey contain gold deposits washed down from the mountains,

thus in ancient times, gold and silver were more plentiful than now.

We parked the car by the side of the road, and got out. There growing out of

the gap between the road and the kerb was a beautiful pink wild rose bush in

full flower. The roses were beautifully fragrant. This was peculiar because even

in Turkey wild roses are like ours in the UK with hardly any fragrance. When we

told Prof. Baser about this he was very excited and told us he would try and

get a sample. This excitement was because he suspected that roses were

widely used in ancient Turkey, but they had no proof of if the variety was close

to kazanlik or not. Such a find could be very important historically being close

to such an important tomb.

Some year or so after this, the BBC made a program about a feast that was

held as part of the burial process. The nature of the feast was known from

pollen and other remnants excavated in the assembly area opposite the tomb

entrance. Doubtless flowers were part of the ceremony and who knows of

seeds might have kept self propagating over the thousands of years. There is

no other housing close to the tomb to disrupt natural processes.

Next we visited the museum and then crossed the road to enter the mound.

This huge mound had never been robbed or been excavated until the middle

1950s - strange for a tomb sticking out like a sore thumb and in a populated

rural area. Tomb robbing has always been a village pastime anywhere in the

ancient world. This is something to consider when I tell you about other things.

The entrance is a long tunnel mined into the mound. As we got to the entrance

I said to Butch “this is on an earth energy centre” I can feel these natural

energies in a similar way to dowsing. The central chamber is an amazing

structure and is I think unique. The tomb chamber itself was built of multiple

walls of juniper logs filled in with rocks and with stone roof supports. Many of

those 2500 year old logs are still there. The whole structure looked to me like a

massive electrical insulator. When the tomb was first excavated it was found

packed with beautiful gold treasure as well as the remains of the king. The

whole lot is now in Ankara museum, but what remains is some kind of energy

centre. Not uncommon of course in earthquake zones, but the ancients sure

knew how to utilise these emanations. Continued.

Butch took several photos in the tomb and outside. I didn’t take my camera in

because I knew I could get copies from him. Later after I got home, Butch said

the whole reel had come out blank. Yet other films on the trip were fine, so it

wasn’t the camera.

Later at the hotel, we started searching our pockets. I had mislaid one of the

leaves we picked off the rose bush to show Prof. Baser. I then found the file of

rose oil we were both given at Gulbirlik and had a quick sniff of mine.

Immediately I knew it had changed. Butch checked his and then compared it to

the main batch of oil he had left in the car. The sample in the car was quiet

different to the sample we took into that tomb. I do not know what happened,

but am sure whatever this radiation is, that it had affected the oil. I have here

samples of the two oils. One is the file that went into the tomb, the other the

batch that it came from. You may only be able to tell the difference if you have

a good nose. I won’t say anything about the difference you tell me what you

think. I must say that I am certain all the talk about ‘energies’ in essential oils

and their healing effects via this pathway is just aromatherapy hype. However,

earth energy centres do exist and have effects as yet largely unknown. I can

also tell you that I felt and looked 5 years younger when I came back from this

trip, people even commented how much less strained I looked. So those that

are contemplating a facelift, perhaps a quick trip to turkey and a visit to this

tomb might be cheaper and far less painful.

-----------------------------------------------

Tue, 10 Mar 2015

Dear Martin Watt,

There are some small changes between the lines. But the method of the

production and the rose is same. For example, we have built a new rose

concrete plant out of the city. Its capacity is 2 times more than old one. We

have put new second distillation boilers which are continuous system. We put

new boilers which is produced aromatic compound from the waste water of

second distillation. But the most important thing is we have a large cosmetic

production line under Rosense brand. We have exports too many countries with

Rosense products.

May be you need to come and visit Isparta again. :)

rosense.com gulbirlik.com

Source and copyright: aromamedical.org

334

More posts