Rosemary oil (Tunisian) - growth and production

Essential Oils Production & Conservation/

23.02.24

ROSEMARY OIL

(Tunisian)

Its growth and production

By Martin Watt

Its growth and production

By Martin Watt

In 1995 I was part of an aromatherapy tour visiting Tunisia organised by Clive

Bendon of Quality Analysis Ltd. UK. qal.uk.com The prime objective was to see

the rosemary oil being produced, although we also hoped to see Neroli

production.

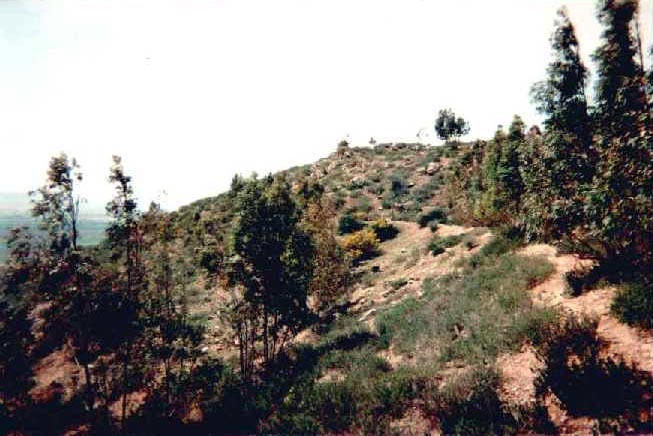

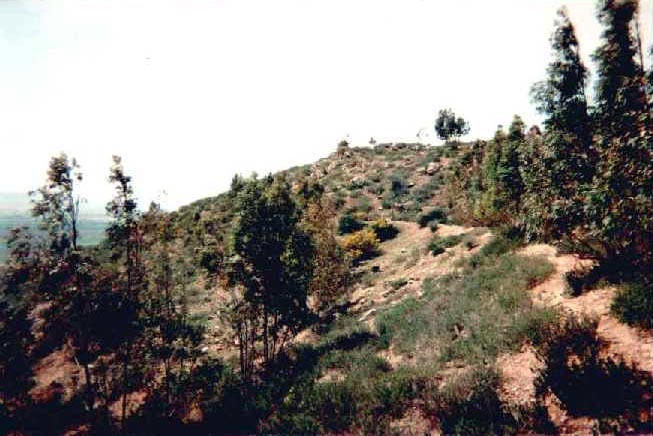

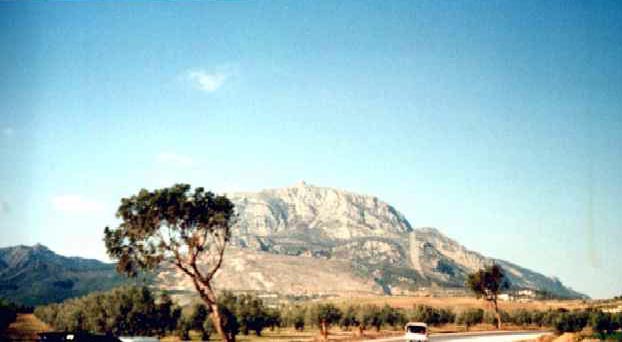

Rosemary grows wild in Tunisia and many of the hillsare covered with the bushes - see image below.

All photographs © 1995 copyright M. Watt.

The bushes are wild and not subjected to fertilisers and pesticides. However, if

the plants were originally planted on these hills only a historian of French

colonial agriculture would know. My suspicion is they were planted - maybe a

hundred years or more ago - because there are many pieces of old clay pots

lying around. We should remember that the French fragrance industry

exploited most of their colonies for fragrance materials.¨)

The area we headed to was about 70 miles inland from the Mediterranean

coast close to the village of Medjeb el bab. Here lies a large plain covered with

various crops. In the distance can be seen the low hills where the rosemary

grows. As you approach the hills you can see the green shimmer of the

rosemary. In places you could see what looked like bare scars running across

the hills (see above). These scars were firebreaks, which in this hot dry climate

were badly needed. Just imagine a hill covered in aromatic plants such as

rosemary catching fire!

As we drove up the dirt roads in the foothills, you could see other plants dotted

between the rosemary. These were the occasional Myrtle bush, plus quick

growing Eucalyptus trees planted to stabilise the loose rocky soil and to

provide firewood.

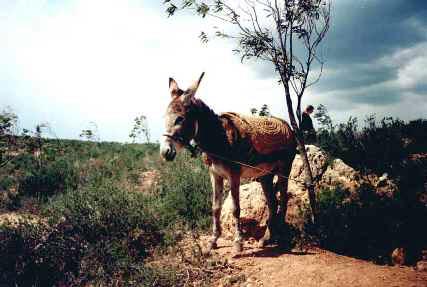

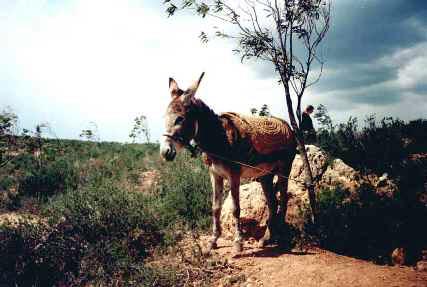

The track wound its way up the hill and in so doing it divided the hill into

separate sectors. This meant that as the rosemary was harvested, there was

no need for the workers to scramble up the steep slopes. Instead they used

donkeys that could amble along the road until they reached the rosemary heap

near the still. The donkeys were loaded up with huge bundles of rosemary tied

up with sacking. Although the load looked huge, it was of course mostly air and

so not too heavy.

We were told that the rosemary could be harvested twice a year. One hillside

was harvested then the still was shifted to another one. By the time the other

areas had been harvested over a 3-month cycle, the original plants had

regrown and could be harvested again. Then the whole area was left alone

until the next year.

All harvesting was done by hand by the men from the nearest local villages.

They camped out on the hillsides during the production season under simple

shelters made of a few wooden poles and plastic sheeting. There were no toilet

facilities other than a hole in the ground so you could say the plants were truly

organically grown! All their needs of food, water, etc. were bought up from the

village in pickup trucks.

The only things needed for producing the rosemary oil that were not available

on the hills was water and the stills themselves.

As can be seen from the photos, the stills are large thick walled steel drums

about 2 metres in diameter and about 1.5m high. A platform is made of soil

and rocks so that the still can be placed over the fire.

The primary still is filled with water and freshly cut rosemary. This process is

known as hydro distillation and is exactly the same as cooking your vegetables.

The fact the herb is immersed in water means the oil is not so chemically

degraded as can occur with hot steam distillation. The conical lid is then placed

over the still and is partly sealed with mud. The lid has a pipe that leads the

aromatic vapours rising from the rosemary into the cooling condenser next to

the primary still. The cooling condenser is filled with cold water with a coil

running though it which condenses the hot still vapours. At the base is the

receptacle in which the condensate of oil and water falls. Once there, as the

mixture cools, the oil floats to the top and is siphoned off into another

container. Finally, the oil is poured into barrels and taken to the storage areas

by truck.

Once the rosemary charge has been exhausted, (that is a judgement made by

the foreman based on experience), it is forked out onto the hill and dries out in

the bright sun. It is this spent material that is used to fire the still (see below).

Therefore, the whole process can be considered as extremely 'environmentally

friendly' as only the water is taken to the site. Everything else comes from the

soil and the sun.

The smell coming from the still during the processing is divine. If only you

could bottle the air! With this kind of open-air distillation a lot of the highly

volatile gases that occur in the plant are lost to the atmosphere. The only way

such highly volatile compounds can be captured is to use cold processes such

as solvent extraction. However, often these natural compounds are so unstable

that they cannot be captured and preserved. The only way to experience them

is to grow the plants, or be present where they grow. Then on a hot day go

and breath the air, now that is TRUE aromatherapy.

Despite the loss of "top note" volatiles to the air, this Tunisian hydro distilled

rosemary is a top quality oil. Any hydro distilled rosemary oil will be far

superior to steam distilled oil. The way to tell a steam-distilled oil from hydro

distilled is quiet simple. If the oil smells more like eucalyptus the chances are it

is steam distilled. A good quality hydro distilled rosemary should smell almost

the same as the fresh herb. Turkish hydrodistilled rosemary has a similar

fragrance to the Tunisian oil.

Bendon of Quality Analysis Ltd. UK. qal.uk.com The prime objective was to see

the rosemary oil being produced, although we also hoped to see Neroli

production.

Rosemary grows wild in Tunisia and many of the hillsare covered with the bushes - see image below.

All photographs © 1995 copyright M. Watt.

The bushes are wild and not subjected to fertilisers and pesticides. However, if

the plants were originally planted on these hills only a historian of French

colonial agriculture would know. My suspicion is they were planted - maybe a

hundred years or more ago - because there are many pieces of old clay pots

lying around. We should remember that the French fragrance industry

exploited most of their colonies for fragrance materials.¨)

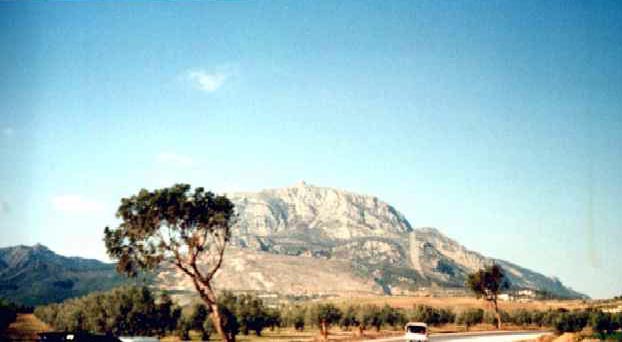

The area we headed to was about 70 miles inland from the Mediterranean

coast close to the village of Medjeb el bab. Here lies a large plain covered with

various crops. In the distance can be seen the low hills where the rosemary

grows. As you approach the hills you can see the green shimmer of the

rosemary. In places you could see what looked like bare scars running across

the hills (see above). These scars were firebreaks, which in this hot dry climate

were badly needed. Just imagine a hill covered in aromatic plants such as

rosemary catching fire!

As we drove up the dirt roads in the foothills, you could see other plants dotted

between the rosemary. These were the occasional Myrtle bush, plus quick

growing Eucalyptus trees planted to stabilise the loose rocky soil and to

provide firewood.

The track wound its way up the hill and in so doing it divided the hill into

separate sectors. This meant that as the rosemary was harvested, there was

no need for the workers to scramble up the steep slopes. Instead they used

donkeys that could amble along the road until they reached the rosemary heap

near the still. The donkeys were loaded up with huge bundles of rosemary tied

up with sacking. Although the load looked huge, it was of course mostly air and

so not too heavy.

We were told that the rosemary could be harvested twice a year. One hillside

was harvested then the still was shifted to another one. By the time the other

areas had been harvested over a 3-month cycle, the original plants had

regrown and could be harvested again. Then the whole area was left alone

until the next year.

All harvesting was done by hand by the men from the nearest local villages.

They camped out on the hillsides during the production season under simple

shelters made of a few wooden poles and plastic sheeting. There were no toilet

facilities other than a hole in the ground so you could say the plants were truly

organically grown! All their needs of food, water, etc. were bought up from the

village in pickup trucks.

The only things needed for producing the rosemary oil that were not available

on the hills was water and the stills themselves.

As can be seen from the photos, the stills are large thick walled steel drums

about 2 metres in diameter and about 1.5m high. A platform is made of soil

and rocks so that the still can be placed over the fire.

The primary still is filled with water and freshly cut rosemary. This process is

known as hydro distillation and is exactly the same as cooking your vegetables.

The fact the herb is immersed in water means the oil is not so chemically

degraded as can occur with hot steam distillation. The conical lid is then placed

over the still and is partly sealed with mud. The lid has a pipe that leads the

aromatic vapours rising from the rosemary into the cooling condenser next to

the primary still. The cooling condenser is filled with cold water with a coil

running though it which condenses the hot still vapours. At the base is the

receptacle in which the condensate of oil and water falls. Once there, as the

mixture cools, the oil floats to the top and is siphoned off into another

container. Finally, the oil is poured into barrels and taken to the storage areas

by truck.

Once the rosemary charge has been exhausted, (that is a judgement made by

the foreman based on experience), it is forked out onto the hill and dries out in

the bright sun. It is this spent material that is used to fire the still (see below).

Therefore, the whole process can be considered as extremely 'environmentally

friendly' as only the water is taken to the site. Everything else comes from the

soil and the sun.

The smell coming from the still during the processing is divine. If only you

could bottle the air! With this kind of open-air distillation a lot of the highly

volatile gases that occur in the plant are lost to the atmosphere. The only way

such highly volatile compounds can be captured is to use cold processes such

as solvent extraction. However, often these natural compounds are so unstable

that they cannot be captured and preserved. The only way to experience them

is to grow the plants, or be present where they grow. Then on a hot day go

and breath the air, now that is TRUE aromatherapy.

Despite the loss of "top note" volatiles to the air, this Tunisian hydro distilled

rosemary is a top quality oil. Any hydro distilled rosemary oil will be far

superior to steam distilled oil. The way to tell a steam-distilled oil from hydro

distilled is quiet simple. If the oil smells more like eucalyptus the chances are it

is steam distilled. A good quality hydro distilled rosemary should smell almost

the same as the fresh herb. Turkish hydrodistilled rosemary has a similar

fragrance to the Tunisian oil.

Source and copyright: aromamedical.org

319

More posts